PRODUCT

eMap

System Introduction

In complex semiconductor manufacturing environments, supply chain equipment is highly diverse and interconnected, spanning multiple departments with intricate dependencies. A single point of failure—if not detected and addressed in time—can lead to substantial financial losses or even large-scale safety incidents. eMAP is an integrated monitoring and emergency management platform that connects critical facility systems—including ultrapure water, process gases, power, and HVAC—with plant-wide personnel and alarm data. Equipped with real-time automated alerting and a visualized command interface, eMAP enables intuitive hazard identification and rapid incident assessment. It provides a comprehensive view of abnormal events, pinpointing their locations and assessing impact areas to support fast and effective emergency response and fault resolution. By significantly shortening response time and improving decision-making under pressure, eMAP helps prevent operational disruptions, minimize losses, and enhance overall plant safety.

Product Features

System Architecture

Application Scenarios

Construction process

System Requirements

Product Features

Product Features

System Architecture

Application Scenarios

Construction process

System Requirements

Product Features

Alarm Integration and Real-Time Monitoring

Multi-source Alarm Integration

Synchronized Monitoring Across Multiple Plant SCADA Systems

Data Link Visualization

Text and Graphics Visualization

Enhances Readability and Tangibility

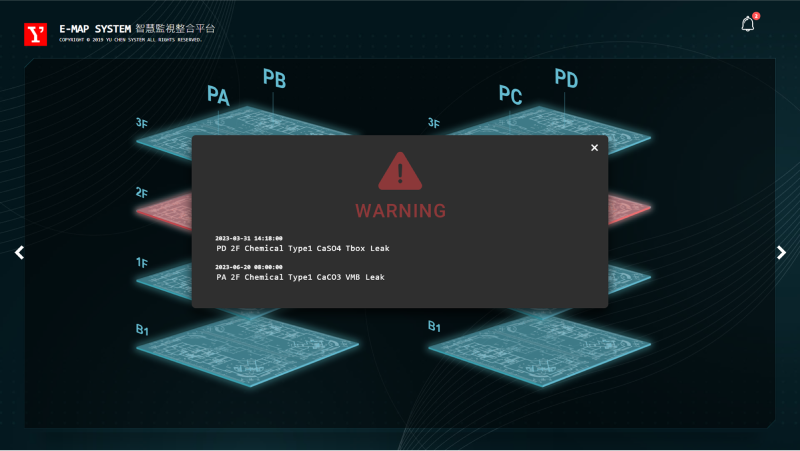

Real-Time Alert Notifications

Automated Dispatch

Multiple Notification Channels

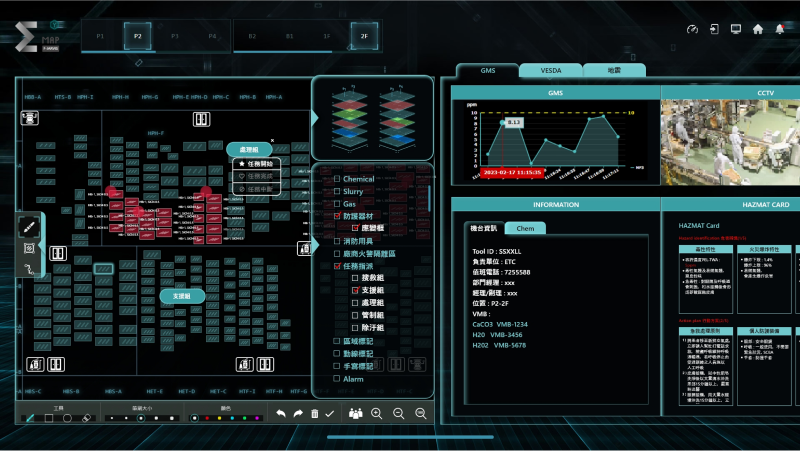

Supply Chain Status Overview

Real-Time Monitoring of All Plant Equipment

Clear Traceability of Master-Slave Relationships

Clear Traceability of Master-Slave Relationships

Cross-Platform Data Integration

One-Stop Access to Multi-Platform Data

Automatic Correlation Linking

Transparent Information to Prevent Data Silos

Intuitive Operation

65-Inch Touchscreen Display

User-Friendly and Easy to Use

Customized Scenarios Tailored to Your Needs

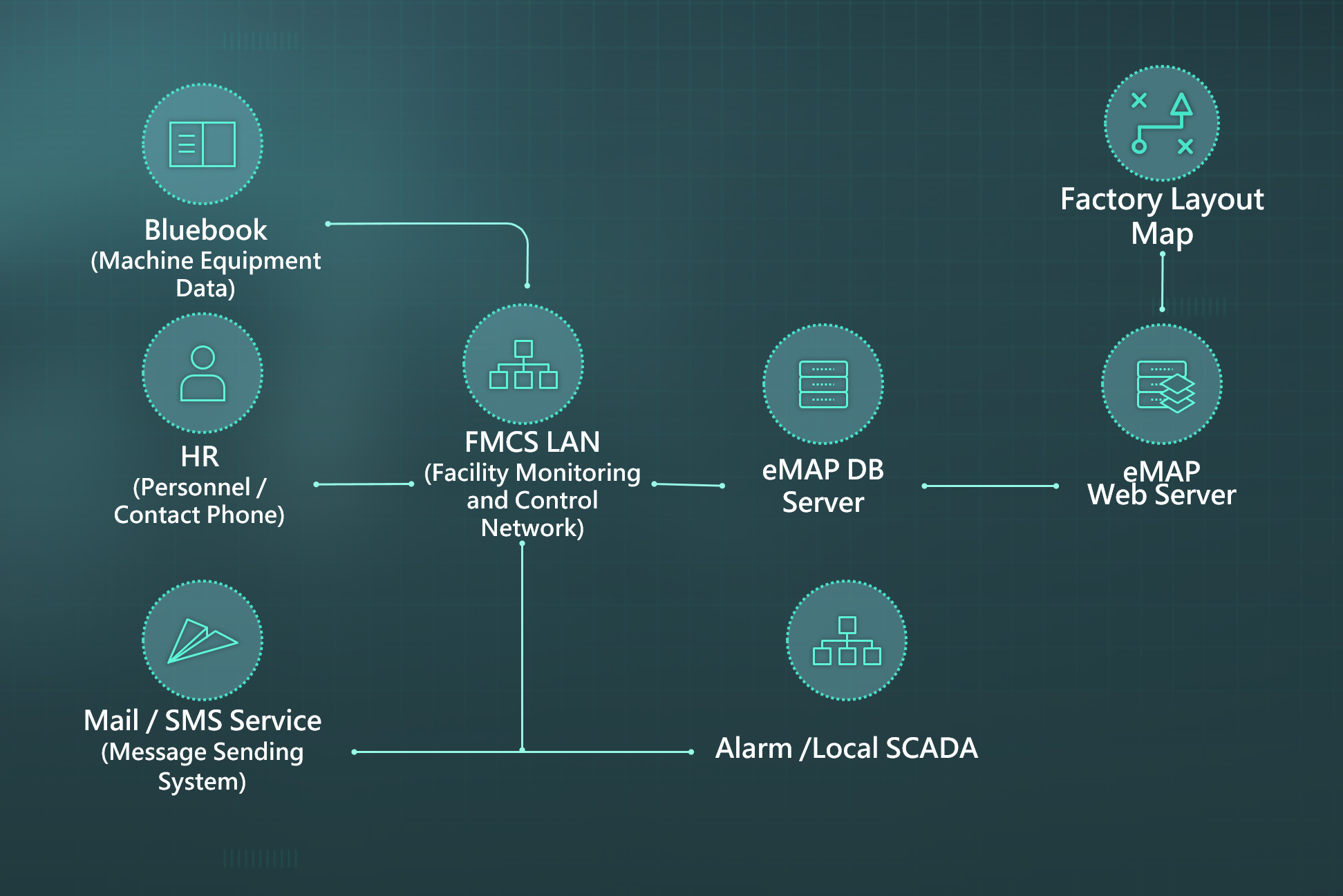

System Architecture

Application Scenarios

Hookup

Equipment Maintenance

Automatically updates equipment data to reflect the latest facility supply status.

Genealogy Maintenance

Synchronizes database content in real time to prevent data omissions caused by manual operations.

Demand Assignment

Automatically matches available points from the database, reducing time spent on on-site searching.

Facility Monitoring

Facility Monitoring

Cross-Department Notification

Backend Maintenance

Automated data synchronization enhances data integrity and maintainability.

Supply Chain Status

Tree-structured overview of the supply chain with real-time visibility into anomaly impact zones.

ISEP

Composite Alarms

Composite Alarms

Emergency Response

Touchscreen interface replaces traditional whiteboards, automatically linking to response information.

Event Logging

Event Logging

Report export and incident analysis support effective post-incident reviews and emergency drills.

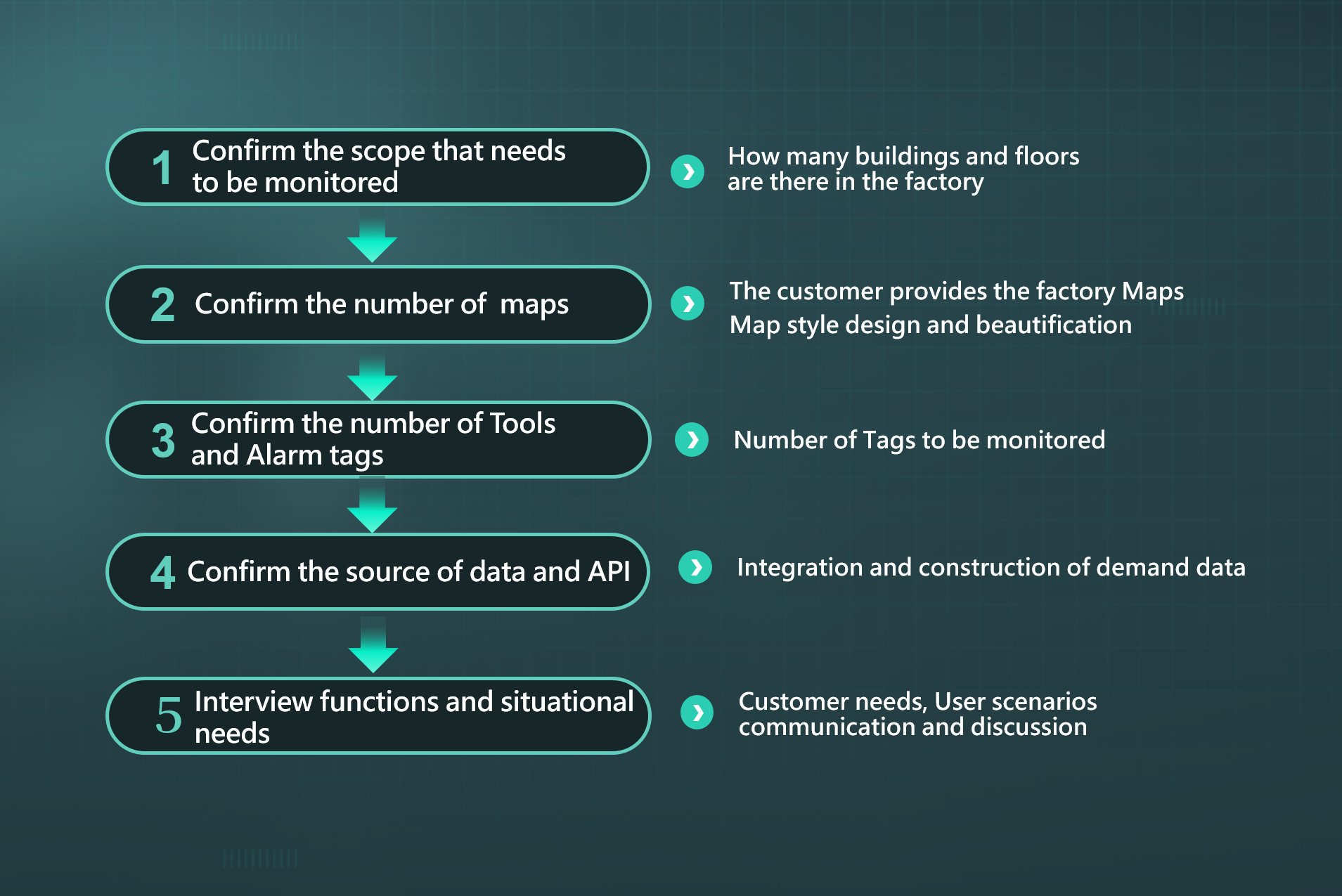

Construction process

System Requirements

【Hardware】

DB SERVER

WEB SERVER

THIN CLIENT

Touch screen (65/55 inches)

Port numbers

【Software】

OS:Windows 10 Professional or higher

Google Chrome 80 or higher

Windows Server 2012 R2 Standard or higher

SQL Server 2017 or higher

.NET 4.8 or higher

Office 2016 or higher

TOP

TOP